Add to Cart

A cable tray roll forming machine plays a crucial role in the manufacturing process of cable trays. Cable trays, also known as cable management systems, are essential structural components used to support electrical cables, wires, and other communication or control elements in buildings and industrial facilities. The roll forming process involves using this specialized equipment to shape and fabricate continuous lengths of metal into the precise profile required for cable trays.

The cable tray roll forming machine is a highly efficient and precise piece of equipment. It is designed to handle various types of metal, including steel, aluminum, and stainless steel, and can produce cable trays in different sizes and shapes. The process begins with feeding the metal coils into the machine, where it is then shaped and cut into the desired length. The machine's speed and precision ensure a consistent and high-quality output, making it ideal for mass production of cable trays.

The use of a cable tray roll forming machine offers many advantages in the production of cable trays. Some of these include reduced labor costs, increased production efficiency, and improved product quality. Additionally, this equipment allows for customization options, making it possible to produce cable trays with specific features or designs to meet various project requirements.

In conclusion, the cable tray roll forming machine is an essential piece of equipment in the manufacturing process of cable trays. Its versatility, efficiency, and precision make it a vital component in producing high-quality cable trays for various applications.

Features:

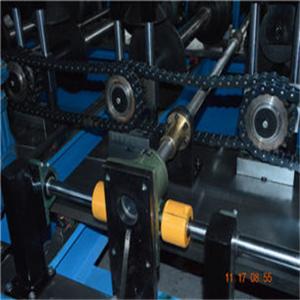

Features: The roll forming process is used to shape metal coils or strips into the desired profile for cable trays. This process involves passing the metal strip through a series of rollers, each performing a specific bending or forming operation to achieve the final shape.

An uncoiler is utilized to hold and unwind the metal coil, allowing for a continuous feeding of material into the roll forming machine. A leveling system may also be included to ensure that the metal strip is flat and uniform before entering the roll forming section.

Multiple sets of roll forming stands are arranged along the machine to perform sequential bending and forming operations on the metal strip. Each stand contributes to forming different features of the cable tray, such as the sides, bends, and perforations.

Cable trays often feature perforations or holes for ventilation, cable entry, and drainage. To accommodate this, the roll forming machine may include a perforation or hole-punching station.

A cutting system is integrated to cut the continuous length of formed cable tray into individual sections of the desired length. This ensures that the cable tray components are accurately cut to the specified dimensions.

Modern cable tray roll forming machines often feature automated controls, allowing for precise adjustments to the forming process. Computer Numerical Control (CNC) systems may be employed to control the machine's operations, ensuring accuracy and repeatability.

The production speed and capacity of the machine depend on factors such as the complexity of the cable tray profile, material thickness, and the specific design of the machine.

Safety features, including emergency stop mechanisms and safety guards, are essential to ensure the safe operation of the machine and the protection of operators.

Technical Parameters:

| Cable Tray Roll Forming Machine | |

|---|---|

| Main Motor Power | 22KW |

| Condition | New |

| Rolling Thickness | 1-2mm |

| Raw Material | Galvanized Sheet |

| Shaft Material | 45#steel |

| Cutting | Hydraulic Cutting Cr12mov |

| Capacity | 10-12m/min |

| Hydraulic Oil | 46# Hydraulic Oil |

| Quality System | ISO |

Applications:

Cable trays: Essential Components for Efficient Cable Management

Cable trays are versatile structural elements that are widely used in various industries for organizing, supporting, and protecting electrical cables and wiring systems. They provide a practical and efficient solution for managing the extensive network of cables within commercial buildings, industrial facilities, and other settings. Here are some common applications of cable trays:

Commercial and Industrial Buildings

Cable trays are extensively used in commercial and industrial structures, such as office buildings, manufacturing plants, and warehouses, to organize and support electrical wiring systems. They ensure that cables are neatly arranged and easily accessible for maintenance and repairs.

Power Plants

In power generation facilities, cable trays play a crucial role in managing the complex network of power cables, control cables, and instrumentation cables used in various processes. They provide a safe and efficient way to route and protect these vital cables.

Oil and Gas Industry

Cable trays are essential in oil and gas facilities, where they are used to support and protect cables in challenging environments, including offshore platforms, refineries, and petrochemical plants. They offer a durable and corrosion-resistant solution for cable management.

Petrochemical Industry

Cable trays are also used in chemical processing plants, where the presence of corrosive substances requires a robust and durable cable management solution. They support the cables used to control and monitor various processes, ensuring the safe and efficient operation of equipment.

Data Centers

In data centers, cable trays play a vital role in supporting the complex network of data cables, fiber optics, and power cables that connect servers, routers, and other networking equipment. They help maintain an organized and efficient data infrastructure.

Telecommunications Industry

Cable trays are commonly used in the telecommunications industry to organize and support the vast network of cables required for communication systems. These include telephone lines, data cables, and fiber optics that enable efficient communication.

Transportation Infrastructure

In transportation infrastructure, such as airports, railway stations, and subway systems, cable trays are used to manage and protect the cables associated with lighting, signaling, and communication systems. They ensure the reliable and safe operation of these critical systems.

Renewable Energy Projects

Cable trays are also used in renewable energy projects, such as solar and wind energy, to support and protect the extensive cabling required for power generation and distribution. They provide a robust solution for managing these vital components.

Chemical Plants

In chemical processing plants, cable trays play a crucial role in supporting cables that control and monitor various processes, ensuring the safe and efficient operation of equipment. They are designed to withstand harsh chemical environments.

Water and Wastewater Treatment Plants

In water and wastewater treatment facilities, cable trays are used to organize and protect cables associated with control and monitoring systems. They help maintain the reliable operation of these vital systems.

Hospitals and Healthcare Facilities

In healthcare settings, cable trays are used to support and organize cables for medical equipment, communication systems, and other electrical installations. They ensure the efficient and safe operation of equipment in hospitals and other healthcare facilities.

Educational Institutions

Cable trays are also used in schools and universities to manage electrical wiring for lighting, power distribution, and communication systems. They provide a safe and organized way to manage the extensive network of cables in these settings.

Automotive Manufacturing

In automotive manufacturing plants, cable trays are used to support the extensive wiring systems used in assembly lines and control systems. They ensure that the cables are properly routed and protected for efficient operation.

Mining Industry

Cable trays are also employed in mining operations to support and protect cables used in equipment control, lighting, and communication systems. They provide a reliable and durable solution for cable management in these challenging environments.

Building Construction and Renovation

During the construction or renovation of buildings, cable trays are often used to organize and support temporary wiring systems. They provide a flexible and efficient solution for managing cables during the construction and renovation process.

FAQ

1. Q: What's the warranty period? (24hours online)

12 months warranty period, starting from the date of the successful installation and commissioning of the equipment at the Buyer’s Installation site. During which all parts damaged because of quality problem will be changed for free.

2. Q: Do you have installation and commissioning service?

A: If buyers come to our factory to inspect, the training to install and operate is provided face to face. If not, manual and video is provided to show how to install and operate.

B: If buyer need we will send technician to buyer site to do installation and commissioning and training.

C: installation and commissioning cost: One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100 per day and visa fee, air tickets fee, accommodation and food, necessary communication, etc.

(Normally ,It takes about a week to install )

3. Q: What’s your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

4. Q: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time

5. Q: You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

6. Q: Do you provide customized machine?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

7. Q: How to visit your factory?

We are in jiangyin city,belongs to Jiangsu province, near Shanghai. If you

arrive at Shanghai Airport,we can pick you up(It is 160 kilometers from

Pudong Airport, about 3 hours.

It's 110 kilometers from Hongqiao airport, about 2 hours; It's 125 kilometers from downtown Shanghai about two and a half hours.

It is very convenient.Please let me know if you have booked the tickets

so that I can prepare and book a hotel for you,we will arrange for car to pick you up.

By high speed train from Shanghai to East Wuxi (Wuxi Dong station), half an hour.

8. Q: How to place order ?

Inquiry---confirm the profile drawings and technical specification and price--- confirm the PI--- arrange the deposit or L/ C--- start production-- do inspection--- Shipment

9. Q: What certificate do you have ?

We have CE and ISO certificate.

10. Q: What are your terms of payment ?

First payment: 40 % by T/ T, second payment: 60% by T/ T, after the successful inspection at seller’s workshop, and before delivery.

11. Q: What can you do if the machine breaks down?

We have 12 months warranty period, if the broken parts can not be repaired, we will send new parts to replace the broken for free.But if the warranty period is over,you need to pat the express fee.We can solve problems through negotiation and provide technical support for the whole life of equipment .